For more than 30 years, NEST Mold Design and Manufacturing has been firmly committed to providing external customers with precise and high performance injection mold design and production services. To date, we have produced over 300 molds for a wide range of applications including life science consumables, medical devices, electronic components, and more.

In order to ensure the performance and quality of each set of precision molds, NEST has a professional maintenance team with more than 50 members, most of whom have more than 10 years of rich working experience.

Their work ensures that our precision molds have excellent high repeatability, durability and short cycle time. Especially in the case of high-volume production in the pharmaceutical and healthcare industries, automation that is precisely coordinated with products, projects and processes has a decisive impact on the quality and economic efficiency of production.

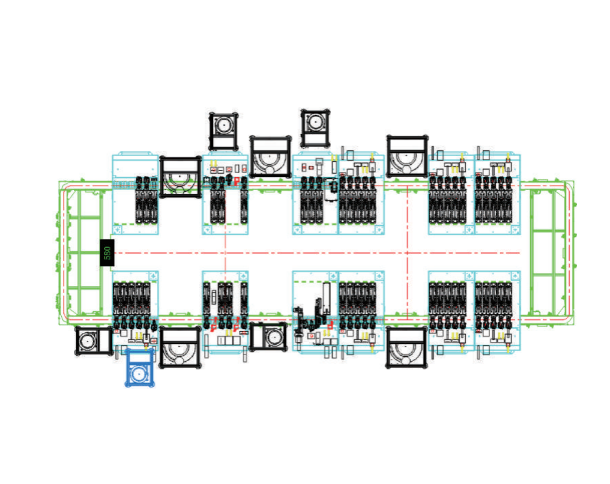

Automation is an integral part of our product and process development. Our expertise is embedded in product development as early as the concept and design stage. Automation solutions are not developed for series production, but already in the prototype and pre-production phase, which saves production time. If an external solution has to be introduced for series production, our knowledge and information can also be shared with the manufacturer of the external automation system.

Feeding with rotor

Gear assembly

Goods/defective goods materialization

Height test

Bracket assembly

In-line press force inspection

Press fitting and test

Pen cap assembly

Torque test (Torque value<4N · cm)