For the certification and validation of pen injectors, we take into account all relevant standards and regulations:

GMP Guidelines (GxP), GAMP5 Guidelines, 21 CFR Chapter 820, 21 CFR Chapter 11, as well as the ISO 9001,

ISO 13485 standards, the MDD 93/42/EEC regulation, the AMG/MPG/AMWHV regulation.

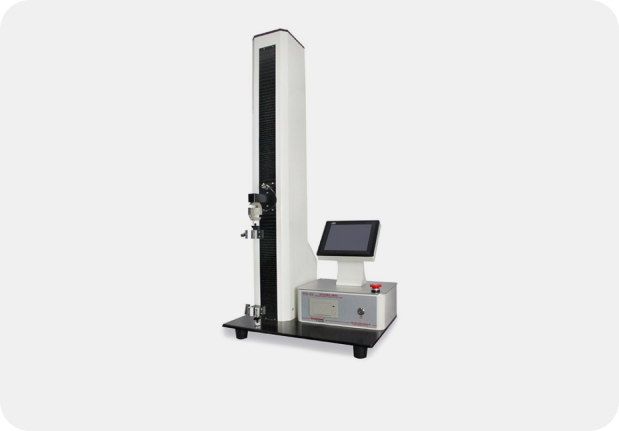

Incoming control of specific materials, physical and chemical analysis

NEST has implemented strict controls on supplier access and approval of raw materials/packaging materials.

We perform detailed material, physical and chemical analyses of plastic pellets and, where necessary, analyze

the causes of damaged parts. Our well-equipped laboratory has the capability to perform physico-chemical

analysis of viscosity, residual moisture and density. In addition, we are equipped with an infrared spectrometer

and thin-section microscope to provide strong technical support for our experiments. Our analytical services

are complemented by in-depth expertise in developing and implementing analytical methods that meet the

individual needs of our customers.

The company ensures that all raw materials/packaging materials meet product technical requirements through

layered control in the following steps:

Supplier questionnaires

Supplier on-site audits

Raw material/packaging material report review

Raw material/packaging material performance validation

Raw material/packaging material batch inspection

These measures ensure the stability of the supply chain and the quality of our products. This section will also

provide declarations regarding NEST's control over raw materials and packaging materials:

Declaration of Raw Material Compliance: (ROHS, REACH)

The raw material particles used in NEST pen injectors are supplied by manufacturers with relevant reports

complying with ROHS and REACH, including but not limited to ABS, PC, PP, etc.

ROHS: NEST strictly complies with the European Union directive "Restriction of Hazardous Substances in

Electrical and Electronic Equipment" (2011/65/EU) (ROHS), which aims to control the use of lead, mercury,

cadmium, hexavalent chromium, polybrominated biphenyls, and polybrominated diphenyl ethers in products.

REACH: NEST strictly complies with the European Union regulation "Registration, Evaluation, Authorization,

and Restriction of Chemicals" (2006/1907) (REACH), which controls the substances of very high concern

(SVHC) in raw materials.

Laboratory for the analysis of materials dedicated to drug

delivery devices and pharmaceutical packaging